DAIRY MACHINERY

BAGS

400 - 800 - 1200 - 2500gr

5 - 10 - 25Kg - 1000Kg

FILLING - FEEDING - PACKING - HANDLING

METAL TIN CANS

400 - 800 - 1500 - 2500gr

Ø99, 127, 153, 189mm

HANDLING - FEEDING - CLEANING - FILLING - SEAMING -C APPING - PACKING

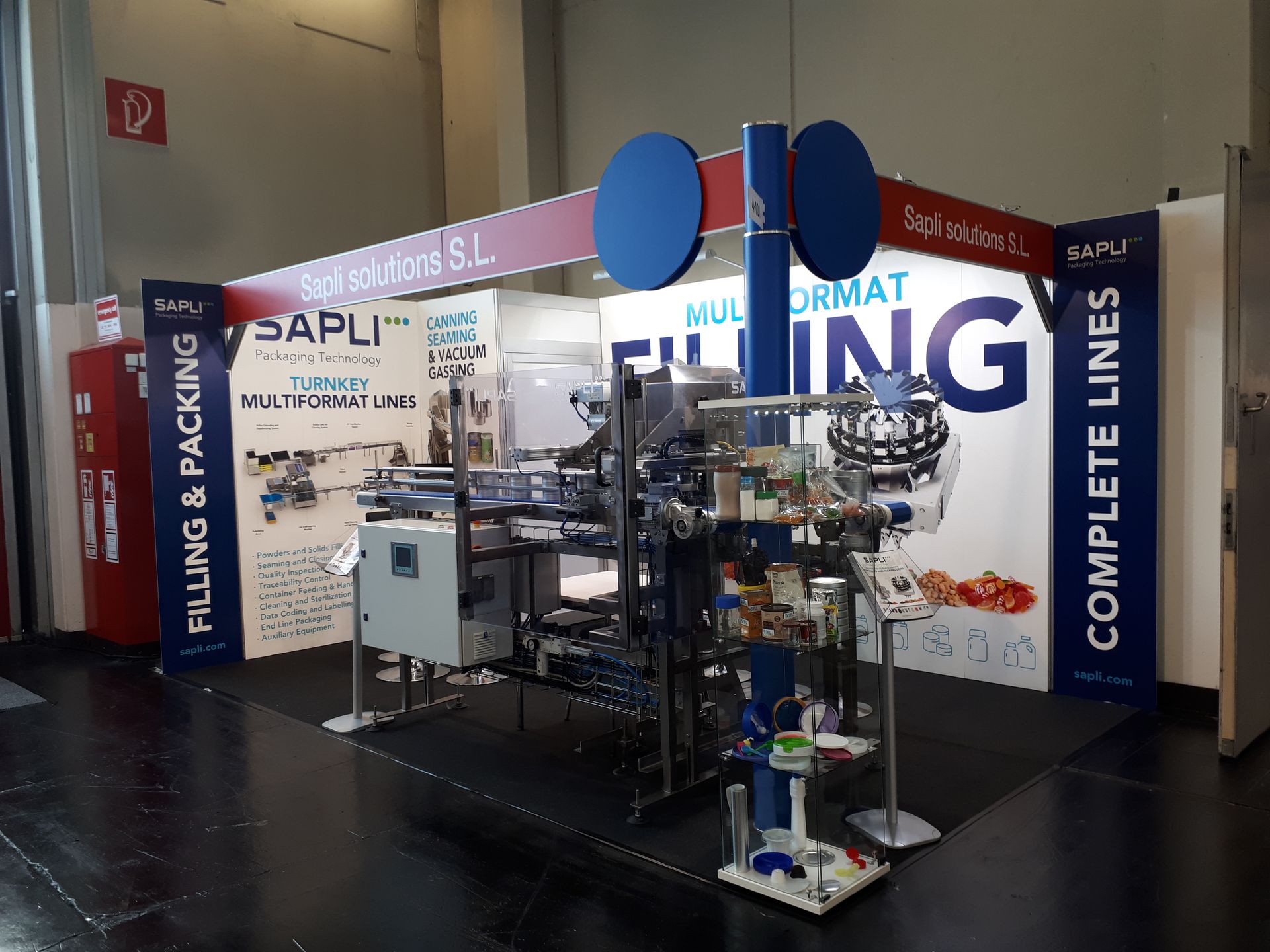

COMPLETE LINES

Low - Medium - High speed lines

Automatic and semiautomatic options

LINES FOR 10-20-30-50-60-120-150 CPM

PACKED PRODUCTS

C A R I N G F O R T H E M O S T I M P O R T A N T

Smart solutions for POWDER

Sapli includes key points in the entire range of its machines for maximum quality.

BAGS PACKING MACHINERY

MULTIFORMAT ADJUSTABLE EQUIPMENT TO LEAD THE PRODUCTION TO THE BEST PRACTICES PERFOMANCE AND QUALITY OUTPUT.

WE OFFER YOU BEST COMBINATION OF MACHINES TO GET THE DESIRED SPEED AND REQUIREMENTS READY TO WORK 24/7 ALL 365 DAYS.

LOW LEVEL OF OXYGEN

NITROGEN INJECTION

CONTROLLED FILLING

BEST QUALITY GUARANTEED

GUARANTEED MACHINE PERFORMANCE

SR-ABG AUTOMATIC BAG FILLING

GET BEST PACKED POWDERED PRODUCT

-WEIGHT RANGES: FROM 50 TO 2500GR

-OUTPUT: 5-10-30-60-100-120 UNITS/MIN

-MACHINE PERFORMANCE: 99%

MR-ABG AUTOMATIC BAG FILLING

GET BEST PACKED POWDERED PRODUCT

-WEIGHT RANGES: FROM 5 TO 25KG

-OUTPUT: 5-10-30 UNITS/MIN

-MACHINE PERFORMANCE: 99%

HR-ABG AUTOMATIC BAG FILLING

GET BEST PACKED POWDERED PRODUCT

-WEIGHT RANGES: UP TO 1000KG

-LIST OF EQUIPMENT FOR BULK FILLING

-REPACKING SOLUTIONS

METAL TIN CANS MACHINERY

MACHINERY TO FULFILL THE HIGHEST STANDARD IN FOOD PACKAGING. EQUIPMENT TO HANDLE, PREPARE AND PACK MILK IN ALL ITS VERSIONS FROM BEGINNING TO THE END OF THE LINE

CANS UNLOADING UNIT - DEPALLETIZER

CANS CLEANER - STERILLIZER

DUST CLEANING UNIT

SPOON INSERTION

FILLING SYSTEMS

SEAMERS WITH MODIFIED ATMOSPHERE

AUGER FILLING SYSTEMS

GET BEST PACKED POWDERED PRODUCT

-WEIGHT RANGES: FROM 50 TO 2500GR

-OUTPUT: 5-10-30-60-100-120 UNITS/MIN

-MACHINE PERFORMANCE: 99%

VOLUMETRIC SOLUTIONS

GET BEST PACKED POWDERED PRODUCT

-WEIGHT RANGES: FROM 50 TO 1250GR

-OUTPUT: 100 TO 250 UNITS/MIN

-ACCURACY 0.5%

SEAMING MACHINES WITH MAP

KEEP QUALITY WELL SEAMED

-HEIGHT RANGE: 30-250mmm

-OXYGEN OUTPUT: BELOW 0.5%

-DIAMETERS RANGE: 50 TO 220mm

COMPLETE LINES SOLUTIONS

MULTIFORMAT ADJUSTABLE EQUIPMENT TO LEAD THE PRODUCTION TO THE BEST PRACTICES PERFOMANCE AND QUALITY OUTPUT.

WE OFFER YOU BEST COMBINATION OF MACHINES TO GET THE DESIRED SPEED AND REQUIREMENTS READY TO WORK 24/7 ALL 365 DAYS.

LOW LEVEL OF OXYGEN

NITROGEN INJECTION

CONTROLLED FILLING

BEST QUALITY GUARANTEED

GUARANTEED MACHINE PERFORMANCE

IFPL- HIGH AUTOMATIC CANNING LINE

HIGH SPEED FULL AUTOMATIC FILLING LINE FOR HIGHEST QUALITY POWDERS:

-OUTPUT: 60 TO 150 CANS/MINUTE

MRMCL- MEDIUM AUTOMATIC CANNING LINE

MEDIUM SPEED FULL AUTOMATIC FILLING LINE FOR HIGHEST QUALITY POWDERS:

-OUTPUT: 30 TO 60 CANS/MINUTE

SRICL - CUSTOME MADE CAN FILLING LINE

LOW TO HIGH SPEED FULL AUTOMATIC FILLING LINE CUSTOMIZED FOR ALL BUDGETS AND FORMATS FOR HIGHEST QUALITY POWDERS:

-OUTPUT: 10 TO 150 CANS/MINUTE

INFANT FORMULA STAR CLASS CANNING LINE

OPTIMIZED SOLUTION WITH THE BEST BALANCE BETWEEN COST AND PRODUCTION FOR NFANT FORMULA AND POWDERED HIGH QUALITY PRODUCTS:

WORKING PLAN

1. Contact us

Contact us by phone, email, or via the contact form. Describe your project and tell us your budget.

2. Receive a quotation from us

Evaluate and discuss with us the options and alternatives or adaptations to specifications.

3. Approve and proceed

You send us PO and samples of the product to be packed. We detail and confirm planning and we start production phase.

4. Project FAT

Equipment is ready in our facilities. Your technical team visit us for Factory Acceptance Test and machine approval before shipment to you.

5. Project SAT

Machines are installed and commissioned in your site. We train operators and maintenance team. You approve machine performance through a Site Acceptance Test.

FAQs

Got a question? We’re here to help.