WHY MAP? (FAQs)

What is Modified Atmosphere Packaging?

Modified Atmosphere Packaging (MAP) is a technology designed to ensure that packaged food stay fresh for as long as possible.

Consider the main factor that causes food spoilage - the oxygen contained in the air can cause a decay process called oxidation. For example, fats and oils in foods can be oxidized, so food becomes rancid. One of the main causes of food spoilage is the growth of germs, bacteria, mold and yeast, which are part of our everyday life.

There are many ways that slow down the spoilage of products, such as preservatives, refrigeration, vacuum packaging. However, keeping food fresh as long as possible without additives is a very difficult task. Therefore, one of the KEY technologies to achieve this goal is the packaging of food in sealed cans / glass jars / capsules, etc. with a strictly controlled proportion of natural gases that suppress the processes of oxidation and the growth of harmful bacteria. Thus, the main goal of this production process is achieved - to increase the shelf life of the product.

How Does Modified Atmosphere Packaging Work?

Oxygen promotes the growth of aerobic spoilage, there is a potential formation of unwanted microorganisms. By reducing the oxygen content and replacing it with other gases, MAP reduces unwanted reactions.

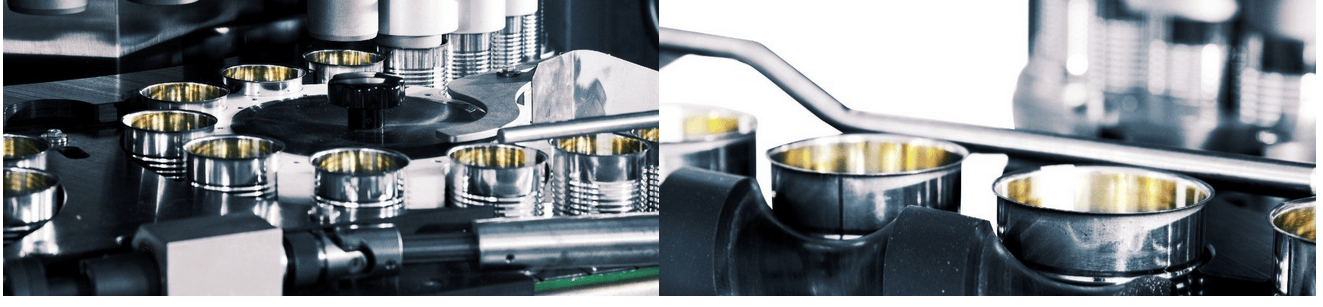

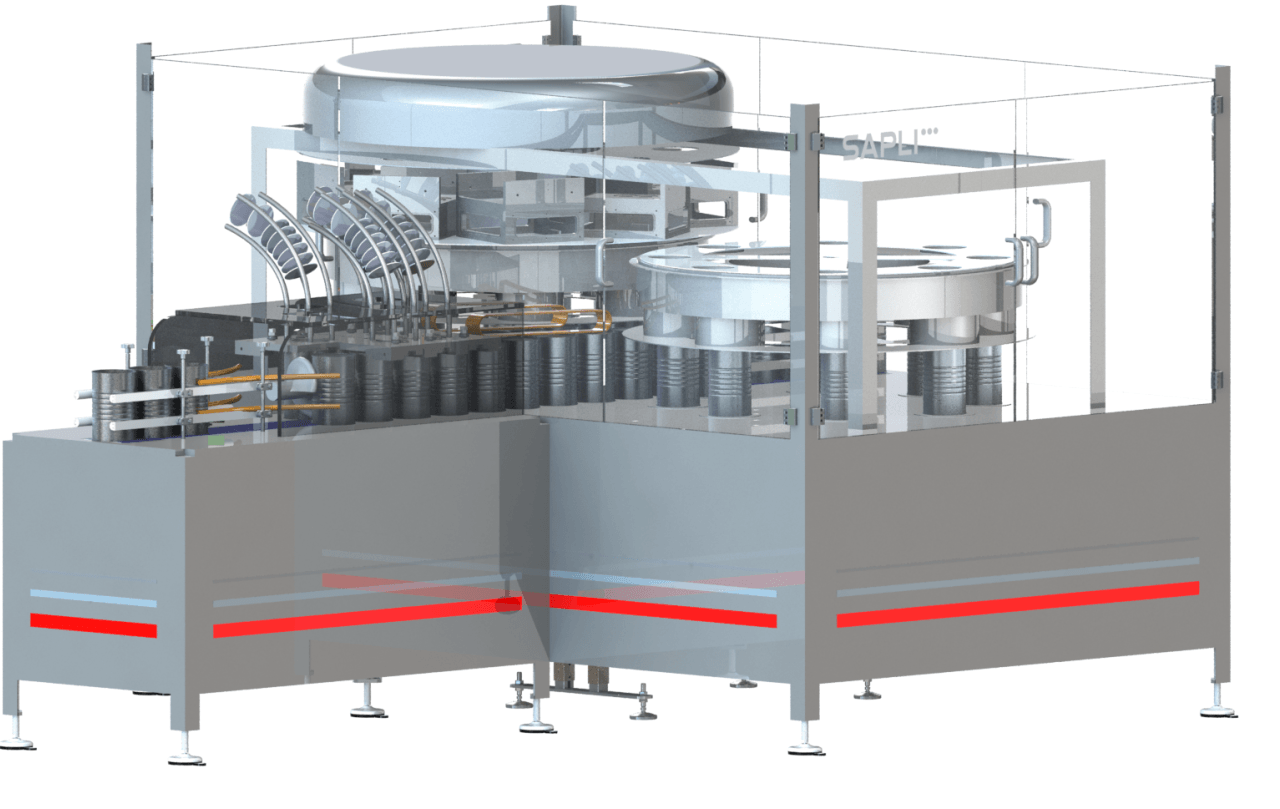

The Sapli´s VACUUMOTION SEAMER

reduces the amount of oxygen contained in the empty space of the packaging containing the product and replaces it with other natural gases such as Nitrogen (N2), Carbon Dioxide (CO2) and others.

The Benefits of Packaging in a Modified Atmosphere

MAP allows you to pack natural products in such a way as to extend the shelf life of the product.

Since MAP does not need chemicals to preserve the freshness of the product. As a result, the product does not contain preservatives, is more attractive to the client.

MAP provides enhanced geographic accessibility.

When it comes to brand recognition, with the consistent quality and freshness of their products, MAP technology is a truly win-win option. Both consumers and food companies enjoy the benefits of MAP.

Recently, consumer demand has shifted towards healthier foods, which are mostly packaged using MAP technology.

Benefits:

- Longer shelf life

- Improved visual appeal

- The product stays fresh longer

- The product does not contain chemical preservatives

- Low salt and sugar content

What products can be packaged using MAP?

A wide range of products can be packaged using MAP technology, namely:

Powdered milk, Infant Formula, Fresh pasta, Fruits and vegetables, Ready meals, Fresh chiken, Fish and seafood, Fresh / Processed Meat, Cheese, Bakery products, Coffee (grain or instant), Cocoa, Various nuts, Snacks.

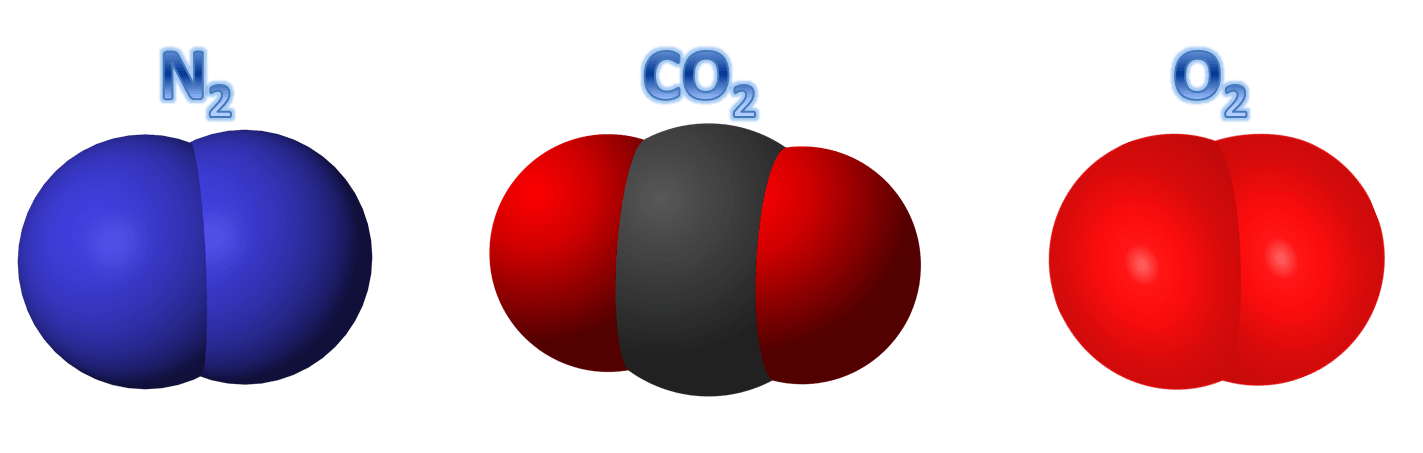

Typical gases for Modified Atmosphere Packaging

The mixture of gases selected for packaging in the Modified Atmosphere depends on the type of product, packaging materials and storage temperature.

The atmosphere in such packages mainly consists of regulated amounts of Nitrogen (N2), Oxygen (O2) and Carbon Dioxide (CO2).

Reducing O2 levels helps reduce the level of oxidation and the development of harmful microorganisms.

A low level of O2 of 1-2% is used for the production of baby food and milk powder.

A CO2 level in excess of 10% is phytotoxic to fruits and vegetables, therefore CO2 is maintained below this level.

CO2, aka Carbon Dioxide, has no color, smell, or taste. It has an inhibitory oxidation and detrimental effect on most aerobic bacteria and mold. Gas is often used to increase the shelf life of a product. The shelf life of packaged or stored foods is generally longer if the level of CO2 is higher. However, many foods can become acidic if the dosage is too high. In addition, the gas may eventually evaporate from the package or be absorbed into the product. The use of supporting or filling gases can slow this effect.

Nitrogen (N2) is an inert gas and, due to its production process, usually has a relatively high purity. It is usually used to displace air, especially atmospheric oxygen, in food packaging. This prevents the oxidation of food and inhibits the growth of aerobic microorganisms. It is often used as a filling gas, as it diffuses very slowly through plastic films and, therefore, remains in the packaging longer and extends the shelf life of the product.

The use of noble gases such as Helium (He), Argon (Ar) and Xenon (Xe) to replace N2 as a balancing gas in the MAP is also possible, but is not used often.

What does it take to pack in MAP?

When considering whether to begin Modified Atmosphere Packaging, several factors must be considered. Below you will find a list of important points to consider:

Basic requirements for starting packaging in MA:

• Gas or gas mixture mixed with a gas mixer.

• Packaging material suitable for MAP - permeability should be consistent with the expected shelf life.

• A packaging machine that is suitable for packaging your product.

• Equipment for quality control and quality assurance

One of the most important points is the correct selection of equipment.

MA packaging requires sophisticated equipment to remove air from the packaging chamber, replace it with another gas or a precisely defined mixture of gases, and then seal the product in the package. Depending on the type of product, the oxygen, nitrogen and carbon dioxide content in the package may vary.

Why Sapli?

Sapli patented the

VACUUMOTION SEAMER, which guarantees a residual oxygen content of less than 2% and consumes N2 or N2/CO2 mixtures of about 330 liters per cycle (approx.) with a productivity of 60 cans / minute, the final figures will primarily depend on the type and properties of the product, the volume and size of cans and the speed of production.

Our VACUUMOTION SEAMER

is able to work with capacities from 400 to 1200 grams, with diameters of 99/127/153 mm (other sizes are also possible).

The machine is designed for seaming metal tin cans, composite cans, glass jars and is suitable for a wide range of formats and heights.

Depending on the type of product, its physical qualities, as well as the model of the machine, the VACUUMOTION SEAMER

is capable of seaming from 7 up to 100 cans per minute.

Sapli offers a unique high-performance can feeding system for vacuum-gassing and seaming. VacuuMotion is specifically designed to minimize the evacuation and seaming cycle to achieve optimal residual oxygen levels.

Thanks to their compact forms, as well as their eco-friendliness, cost-effectiveness and efficiency, these machines can be the ideal solution for both small production facilities and companies with a high level of productivity.