SHELF LIFE OF PRODUCTS WITH THE APPLICATION OF MAP AND WITHOUT

SHELF LIFE OF PRODUCTS WITH THE APPLICATION OF MAP AND WITHOUT

Depending on the requirements for the product, its properties, packaging method and gas concentration.

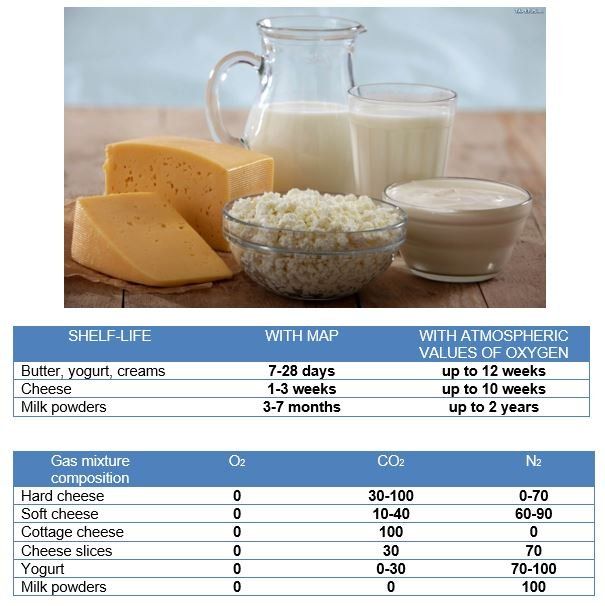

DAIRY PRODUCTS

Cheese spoilage occurs primarily due to the growth of microbes and the resulting rancidity. Chilling food essentially extends the shelf life. On contact with oxygen, there is a danger of mold formation. Therefore, in the past, vacuum packaging was often used, which is inconvenient to open. CO2 effectively prevents the formation of mold without affecting the ripening process of the cheese.

Soft cheese tends to go rancid quickly. Another problem arises with the use of a modified CO2 gas environment. Since soft cheese absorbs much more CO2 than hard cheese, there is a risk that the packaging will lose its shape. Thus, the CO2 concentration should be chosen as low as possible.

When packaging dairy products such as yoghurt or cream, food becomes acidic at high CO2 concentration. Therefore, N2 must be used when packing these products.

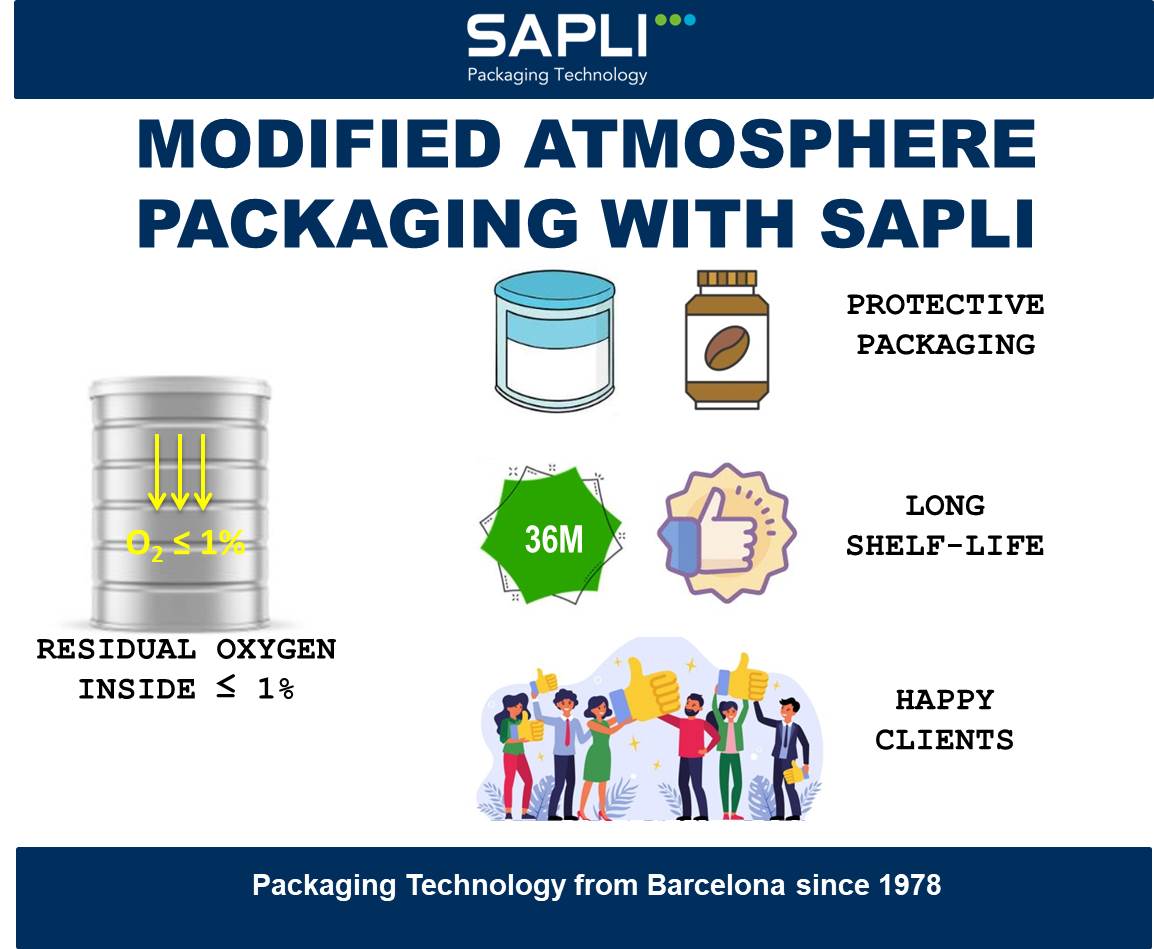

Powdered milk, especially baby food, is a highly sensitive product. To extend shelf life, it is important to displace oxygen from the package by evacuating air and filling with clean nitrogen with low residual oxygen.

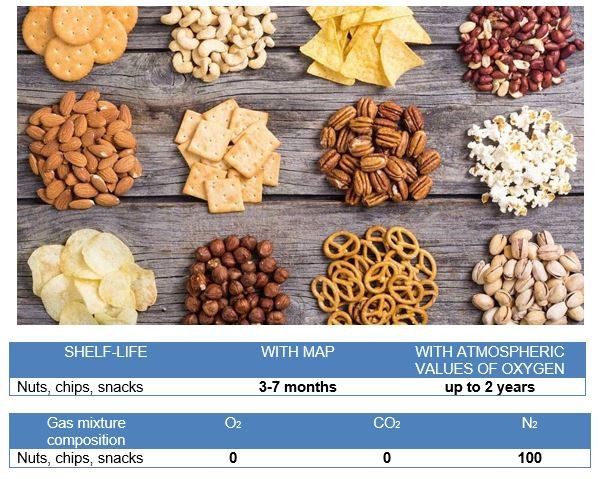

NUTS AND SNACKS

When packing snacks such as potato or meat chips, different types of nuts (peanuts, pistachios, and others), the aspect of the fat content of the products is considered. There is a danger of oxidation, as a result of which the products when

suboptimal gaseous environments become rancid. Therefore, in order to prolong shelf life and maintain taste, it is important to minimize contact with oxygen. Usually, when using MAP, 100% nitrogen concentration is used. In addition to extending the shelf life, on the one hand, the gaseous environment also protects against mechanical damage by maintaining the shape of packaging for fragile products, such as packing potato chips into bags.

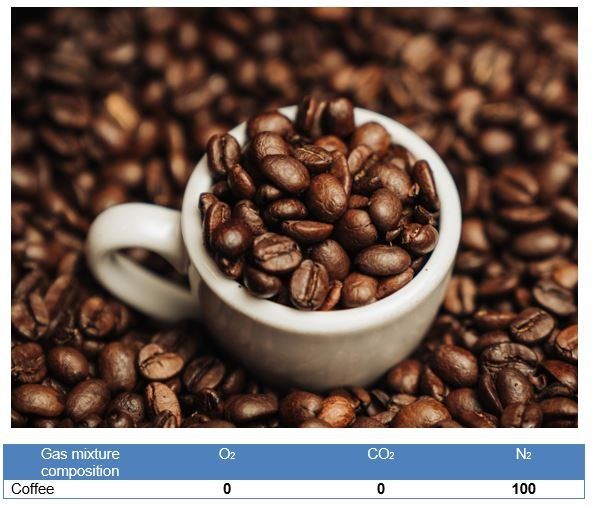

COFFEE

Coffee as a dry product is relatively immune to spoilage by the growth of microorganisms. However, the fatty acids it contains can cause the product to go rancid. To avoid this, coffee is packed without oxygen. The bags or coffee capsules use a modified atmosphere of pure nitrogen.