SHELF LIFE OF MILK POWDERS IN DIFFERENT PACKAGES WITH SAPLI EQUIPMENT

12 May 2020

SHELF LIFE OF MILK POWDERS IN DIFFERENT PACKAGES WITH SAPLI EQUIPMENT

Shelf life is defined as the period between production and the time the food item loses its state of safe and satisfactory quality in terms of nutritional value, microbial status, flavour, texture, and appearance. The packaging plays a fundamental role in maintaining the quality and therefore the shelf life of foods. The package is an integral part of the preservation system and functions as an interface between the food and the external environment; the package should be designed and developed not only to contain the food product but also to protect it and add value to it, as its design may directly affect the purchase decision of the consumer.

A range of variables influence packaging development. In designing a packaging system, trends, prerequisites, conditions, and developments in the external environment must be taken into consideration.

For retailing to consumers, milk powder is packed into either metal cans, composite cans (the body of the can is made of cardboard, the lid and bottom are made of metal) or multilayer pouches. The type and construction of the package depends on the type of milk powder (e.g., skimmed, whole, filled, vitamin-added), the surface area: volume ratio of the package, the desired shelf life, the ambient storage and transport environment, and the anticipated market environment.

WMP, for example, is often packed under N2 gas to protect the product from fat oxidation, maintain its flavour, and extend shelf life. Packaging performance specifications therefore vary and depend on variations in product characteristics, the ambient distribution environment, and the market environment.

Essentially, packaging systems for milk powder must protect the powder from exposure to moisture, O2, and light and anticipate the likely external environmental factors, which include temperature, time, relative humidity, light, and physical hazards.

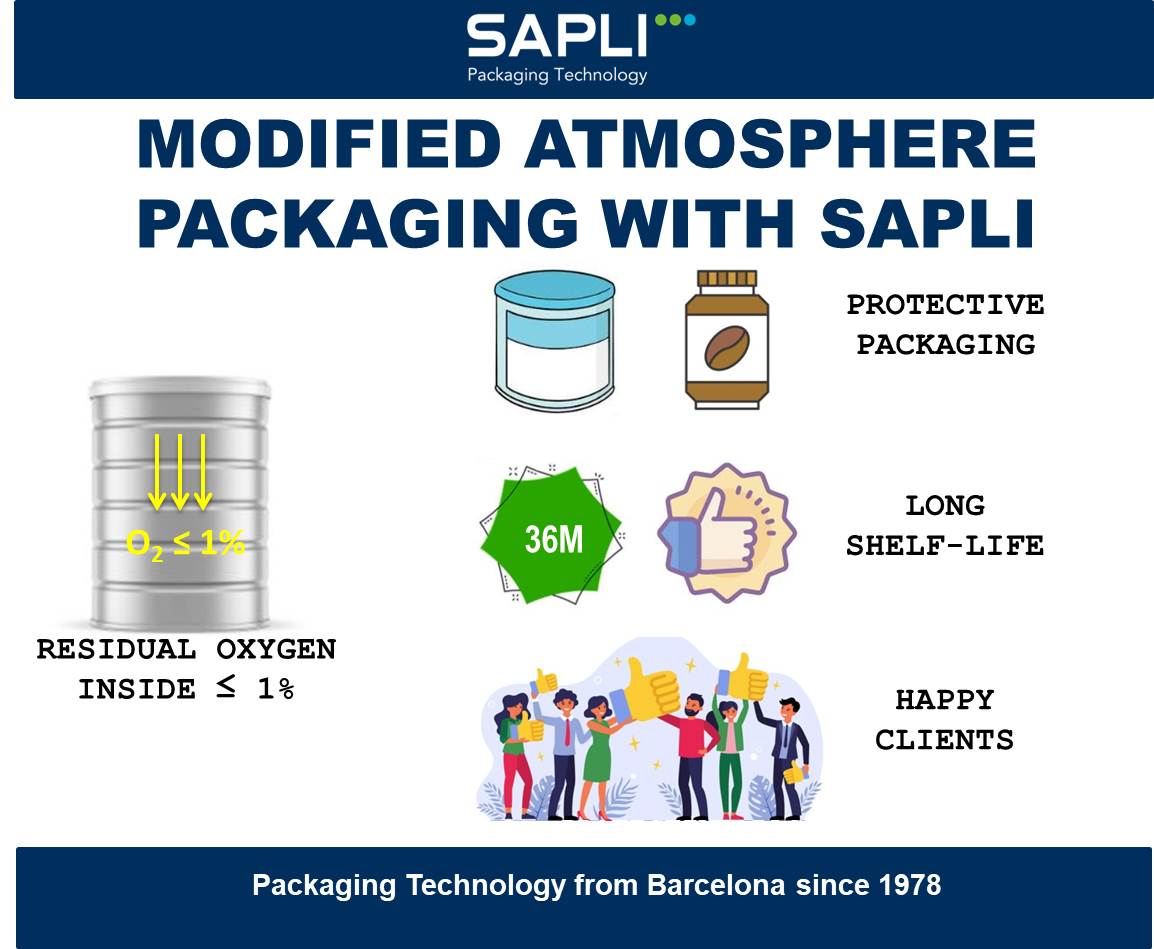

Sapli machines

are specially designed and patented in order to extend the shelf life of powdered milk with various characteristics, as well as for other powdered products, such as coffee beans or instant coffee, various spices, nuts, snacks and many others.

Sapli machines

can work with various types of cans, it can be both metal and composite cans.